How to choose death knives? That's what you need to know

A sheath knife is a best fixed blade knife with a case that is used outdoors such as camping. Various sizes are available, from large long sizes to small lightweight types. You can choose the one that suits your usage from three types: full tang suitable for batoning and chopping wood, concealed suitable for fishing and cooking, and narrow tang. There are also cool products made in Japan with a sense of quality, and it is also recommended as a gift for those who like the outdoors. This time, we will introduce how to choose a sheath knife, recommended products of each manufacturer such as Shimano, mossy oak, Spyderco, mora knife, buck, and how to sharpen the sheath knife.

What is a sheath knife?

Sheath knives are small knives that are often used outdoors. The feature is that the blade part and the grip part that corresponds to the handle are fixed, and you can carry them in a sheath when not in use. Due to the integrated shape of the blade and grip, it is more durable than a folding knife, and it is attractive that it can be used for chopping wood as an alternative to an ax.

Benefits of using a sheath knife

Sheath knives can be used in various camping and outdoor scenes, and have the advantage of having a wide range of applications. We can handle a wide range of tasks, from simple tasks such as handling meat and fish like kitchen knives to wood processing and chopping. Although the knife cannot be folded, many of them are small and can be carried compactly in a case.

How to choose a sheath knife

Choose by type

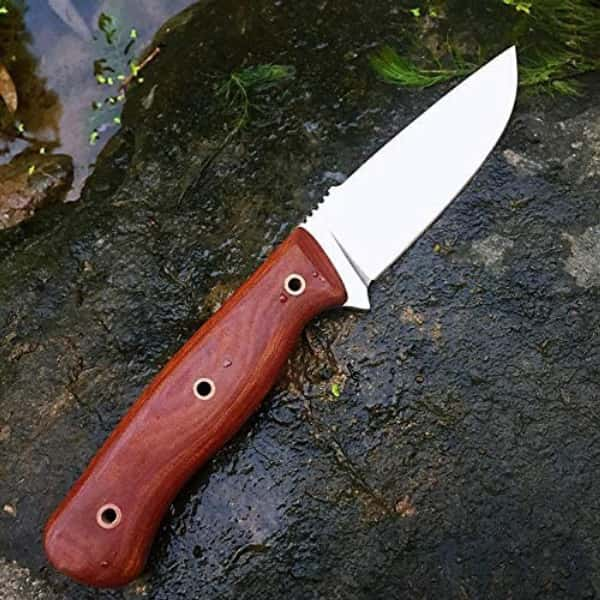

Full tang type that the blade is hard to break

The full tang type sheath knife is characterized by a structure in which the blade part is sandwiched between the handle parts. When viewed from the side, the steel material is exposed in the gap between the handles. Since the blade is attached to penetrate the center, the blade is hard to break and it is suitable for those who want to chop wood in the camp.

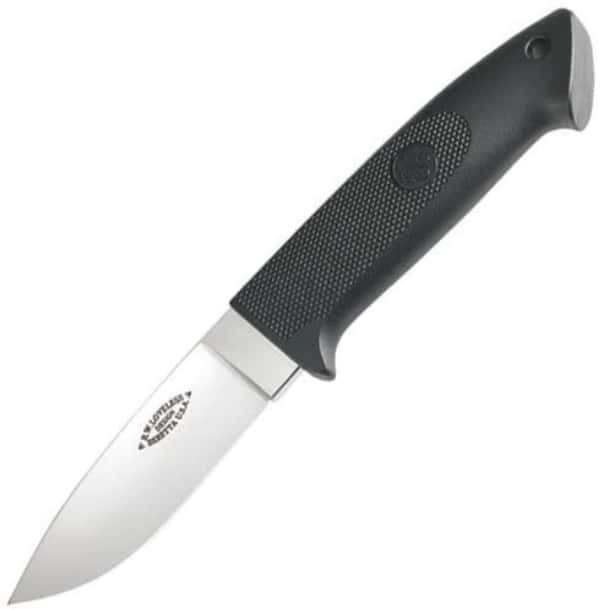

Rust-resistant concealed type

The concealed type sheath knife is characterized by a smaller blade size that is inserted into the handle than the full tang type. Since the steel material is small, it is relatively light and can be easily used even by people with weak power. Since the steel material is not exposed from the handle, it is also an advantage that it is hard to rust. It is not widely distributed and the number of products tends to be small.

Lightweight and an easy-to-use narrow tang type

The narrow tang type sheath knife is characterized by inserting the blade into the hole made in the handle and fixing it. Due to its small size and lightweight, it is suitable for use with portable knives and those with the weak force. It is less strong than the full tang type, so it is recommended for fishing and cooking knives.

Choose according to the application

Recommended for camping

We recommend using a sturdy camping sheath knife that can also be used for padding, which puts a strain on the blade. Banding is the work of breaking twigs and firewood in a campsite with a knife to make it easier to use and is indispensable work for bonfires. A full tang type that is strong against impact is suitable.

Rust-resistant ones are recommended for fishing

We recommend fishing sheath knives that are resistant to rust and have good sharpness. It can be cut smoothly even when the fish caught on the ship is squeezed or handled. If the knife is not sharp enough, you may not be able to handle the fish well and the taste may be lost, so choose one that has a long-lasting sharpness. A stainless steel material that does not rust easily even when it gets wet with seawater is suitable.

Choose by material

Made of easy-care carbon steel

The carbon steel sheath knife has the advantage of being easy to maintain as it can remove rust simply by sharpening it with a whetstone. It is also called carbon steel and is easy to process during manufacturing. It is often used as a material for outdoor knives, and it is also attractive that it can be purchased at a relatively reasonable price.

Made of stainless steel that does not rust easily

Stainless steel sheath knives are characterized by their blades being resistant to rust. It can be used without much care, so it is suitable for beginners who are not accustomed to handling knives. Although the price is slightly higher than that of carbon steel, it is durable and can be used for a long time.

Made of H-1 steel that is resistant to seawater

H-1 steel sheath knives are even more resistant to rust than stainless steel. It is strong against not only freshwater but also salty seawater and is suitable for work in water such as fishing. Although it is not suitable for chopping wood, it has a sharpness that can be used for cooking and handling fish.

Made of molybdenum with long-lasting sharpness

Molybten sheath knives are characterized by their long-lasting sharpness and the blade is not easily chipped. It is a relatively soft and sticky metal, and it has the advantage that it can be easily sharpened to restore sharpness even when it rusts. It can be widely used from padding to cooking and fishing.

Choose with a convenient length

Choose the length of the sheath knife blade that suits your work. The short blade type of about 6 to 10 cm makes it easy to work with the feeling of a fingertip and is suitable for delicate work such as cooking. The long type with a blade of 15 cm or more is suitable for work such as padding because the force is easily transmitted to the cutting edge.

Thick blades are recommended for padding

Sheath knives with thick blades are strong against impact when chopping wood, and have the advantage of being able to efficiently transmit power to wood. However, if the blade is thick, the knife will be heavier, so choose a thickness that is easy for you to handle.

Choose by handle material

A natural material that fits comfortably in your hand

The sheath knife with a handle made of natural wood is easy to fit in your hand and has a beautiful appearance. There are also handles made by processing wood, animal horns, and shells, so you can enjoy the texture and design of the material. Prices tend to be higher, and it is also recommended as a gift for those who like the outdoors.

Affordable artificial lumber

Sheath knives with artificial lumber handles are durable and can be purchased at a reasonable price. Materials such as synthetic resin, stencil, and Micarta are often used, and even the same artificial material has different textures depending on the product. Recommended for those who want a knife that can be used for a long time and those who want to keep costs down.

Check the ease of maintenance

For the sheath knife, it is recommended to use a material that is easy to maintain after it gets dirty or water. Knives made of stainless steel or H-1 steel are rust-resistant and do not need to be sharpened diligently, making them suitable for first-time users. We also recommend carbon steel, which is easy to sharpen.

How to sharpen a sheath knife

1. Prepare the grindstone and knife

First, prepare a knife and a whetstone. There are rough whetstones, medium whetstones, and finishing whetstones, and medium whetstones are recommended for beginners. Soak the grindstone in water for 10 to 15 minutes in advance. Work by placing the grindstone on a wet cloth.

2. How to hold a knife

Drop a few drops of water on the grindstone and sharpen one side of the knife. The blade of the knife should be about 45 to the body, and the blade should be slightly raised so that the angle of the blade and the angle of the grindstone match. The thumb of the hand holding the knife should be held near the base of the knife blade, and the index and middle fingers of the opposite hand should be held under the blade.

3. Sharpen one side of the knife

Move the knife up and down to sharpen it according to the holding method explained in step 2. Use your fingers when pushing the knife forward, and relax when pulling it toward you. After sharpening about 10 times, move the index finger and middle finger, which are being held down, slightly toward the tip of the blade. Move the knife in a circle with the tip of the blade according to the curve of the blade. After sharpening to the tip of the blade, touch the blade edge to check for burrs.

4. Change the knife and sharpen the other side

After confirming the burr, change the knife to the other hand and sharpen from the root to the tip in the same way. After sharpening to some extent, touch the cutting edge again to check if burrs are formed.

5. First, sharpen the sharpened surface several times.

If you can see burrs on the backside, change the knife again and lightly sharpen the first sharpened surface several times. When the burrs on the cutting edge are removed and smooth, rinse the grindstone and knife with water and wipe off the water with a towel.

6. Rub with newspaper to finish

Prepare newspaper or used paper and rub a sharpened knife well to remove fine burrs and debris. Finally, if you make a trial cut and the sharpness is restored, maintenance is complete.

Subscribe to Shieldon (knife manufacturer) channels and we will share useful articles every week.

https://www.facebook.com/ShieldonCutlery

https://www.instagram.com/shieldon_knives_and_tools/

https://www.youtube.com/channel/UC_Dz--HODWHFY4AaUF0z11Q

https://twitter.com/Shieldonknives1/

https://shieldonknivesandtools.tumblr.com/

https://www.linkedin.com/company/72285346/

https://www.pinterest.com/shieldonknivesandtools/

More video introductions:

https://www.youtube.com/watch?v=506F-XXX6v4

https://www.youtube.com/watch?v=JcbY3iwyhfQ

Article source: https://www.shieldon.net/how-to-choose-death-knives-thats-what-you-need-to-know/